Choosing Between Open-Cell and Closed-Cell Packaging Foam

Written by: Foam Factory, Inc.

Both open-cell and closed-cell foam products make great packaging material and come in a variety of shapes and sizes. They both have a unique set of properties, however, which makes each type more appropriate for different packing needs.

When shopping for the right packaging foam from Canada, it’s important to consider how strong the foam needs to be in order to protect the product it surrounds. Open-cell foam is softer because its cell walls are broken, allowing air to fill all of the spaces within the material. Its softness can come in handy for different circumstances.

Open-cell foam products like poly foam are easy to wrap around delicates. Because the material is soft, it can be manipulated and bent to fit inside containers or around items. Poly foam and other soft foams are not meant for long term or vigorous use, though. They are most convenient for one-time shipping and packaging purposes, and they’re highly cost-efficient.

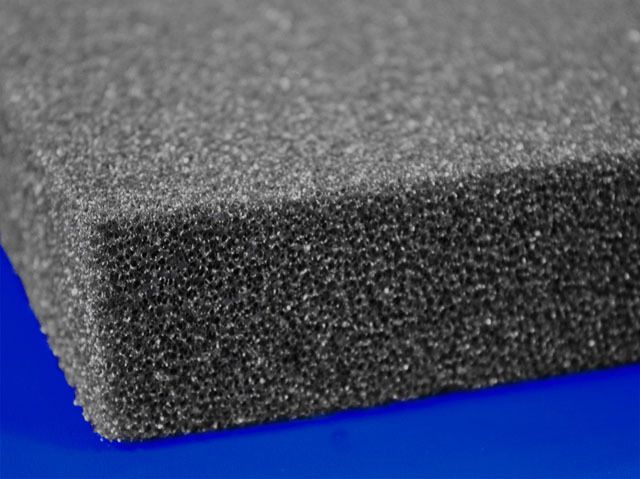

For an open-cell foam that’s built for multiple uses and maintaining a professional look, charcoal high density foam sheets are great options. The increased firmness works well to keep fragile objects packed snugly and safely. This foam works great for technical equipment and

is more resistant to degradation. Due to its dark color, it will maintain a professional look and is less likely to show discoloration due to exposure to light.

Anti-static foam is also open-cell and is great for packing electronics. This product is capable of dissipating electro-static charges given off by neighboring components or the people handling the shipping, keeping the contents of the package safer.

Most of the cell walls in closed-cell foam are not broken. This causes the material to be more firm and rigid, providing different packaging benefits. Polyethylene foam is one type of closed-cell foam from Canada that provides high levels of shock absorption making it ideal for items being shipped long-distance or items that will endure rough handling during their journey.

Polystyrene foam is a firm and lightweight closed-cell product. It is highly resistant to moisture and will not rot or mold. Due to its light weight, it can provide protection for the items being packaged while not adding excessive weight to the overall shipment, helping to keep costs down.

Similar to polystyrene, polypropylene foam blocks are strong and firm, however they have a more durable and plastic-like feel. These blocks are ideal for high-demand packaging applications.